ReconCycle Project: Self-reconfiguration of a robotic workcell for the recycling of electronic waste

Motivation

Currently, electronic waste recycling is still mostly performed following the crude “crush-and-separate” method, where devices are crushed and split into tiny particles, which are then physio-chemically separated into reusable components. Many times this requires first manual work to remove dangerous components or to disassemble sub-parts that cannot go into the crusher.

Recycling companies are here faced with tons of material that arrive in different states of damage and manual pre-processing of this kind constitutes a major (cost-)effort. An inappropriate “alternative” for this is currently still to ship waste to developing countries and abuse their cheap labour to address these problems (or let the waste just be dumped there).

Clearly, there is a very strong incentive to improve on this and this way increase profitability, efficiency, and positive environmental impact of recycling and, thus, even partial automation of some of these steps can make a big difference.

Objective

One specificity of electronic recycling is that usually many different models of the same type but in vastly different conditions need to be dis-assembled, for example, a wide variety of models of mobile phones, hard-drives, or GSM-amplifiers, etc. from different companies. Thus, in this domain we have to deal with large batches of the same type of device, which limits variability at least to some degree, but we are at the same time confronted with many different models within any given device-type and the fact that they are in vastly different conditions, which requires a flexible robotic system that adapts to this.

As a consequence, electronic waste recycling offers an ideal test-bed for self-reconfiguration of robotic cells as the complexity of the required changes within a given device-type is not too high.

Concept and approach

The aim of the project is to introduce self-reconfigurable hardware and software for disassembly of electronic devices, based on a reconfigurable robotic cell developed in the ReconCell project.

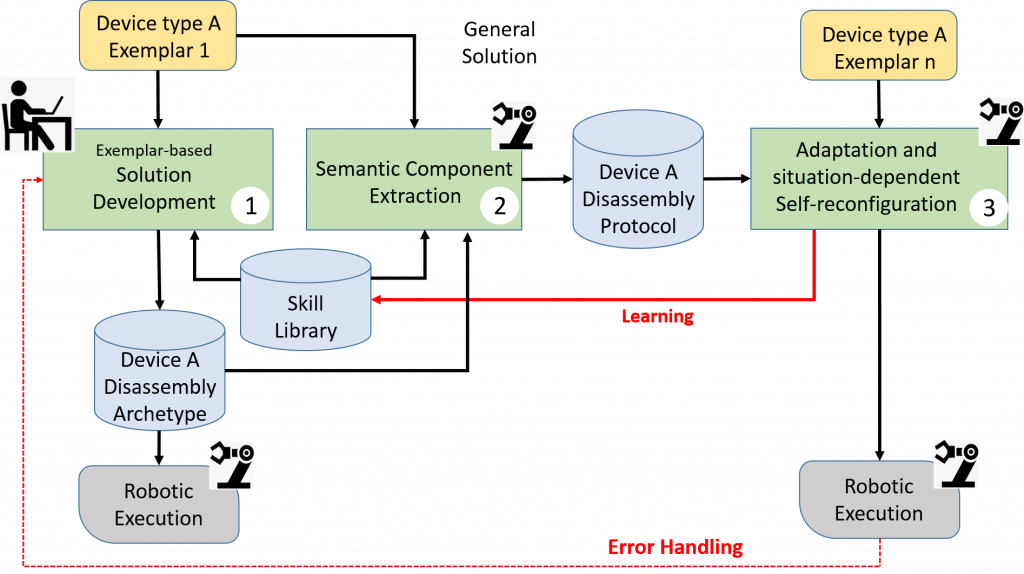

A two-step procedure is foreseen:

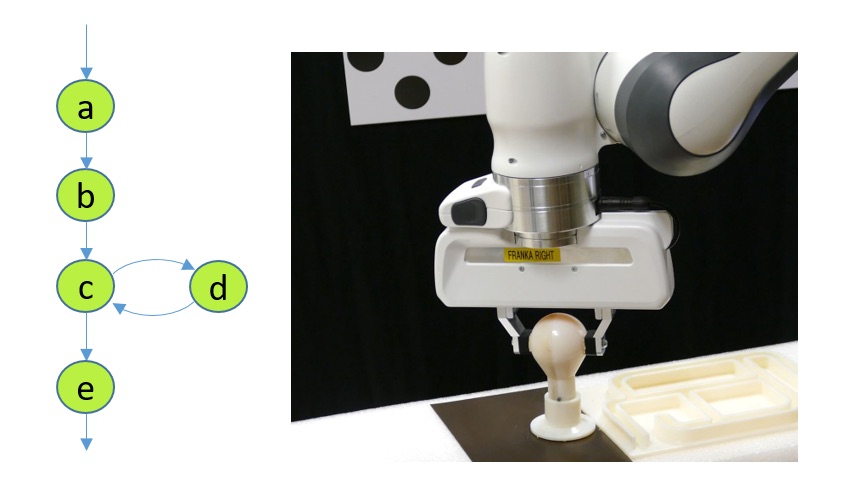

A) When changing from one device-type to another, the reconfiguration shall be performed in an interactive mode, where the application-engineer will be able to provide his/her input.

B) When changing from one device-model to another within a given device-type, the cell shall perform re-configuration (predominantly) on its own through a combination of sensorimotor learning approaches and other AI techniques.

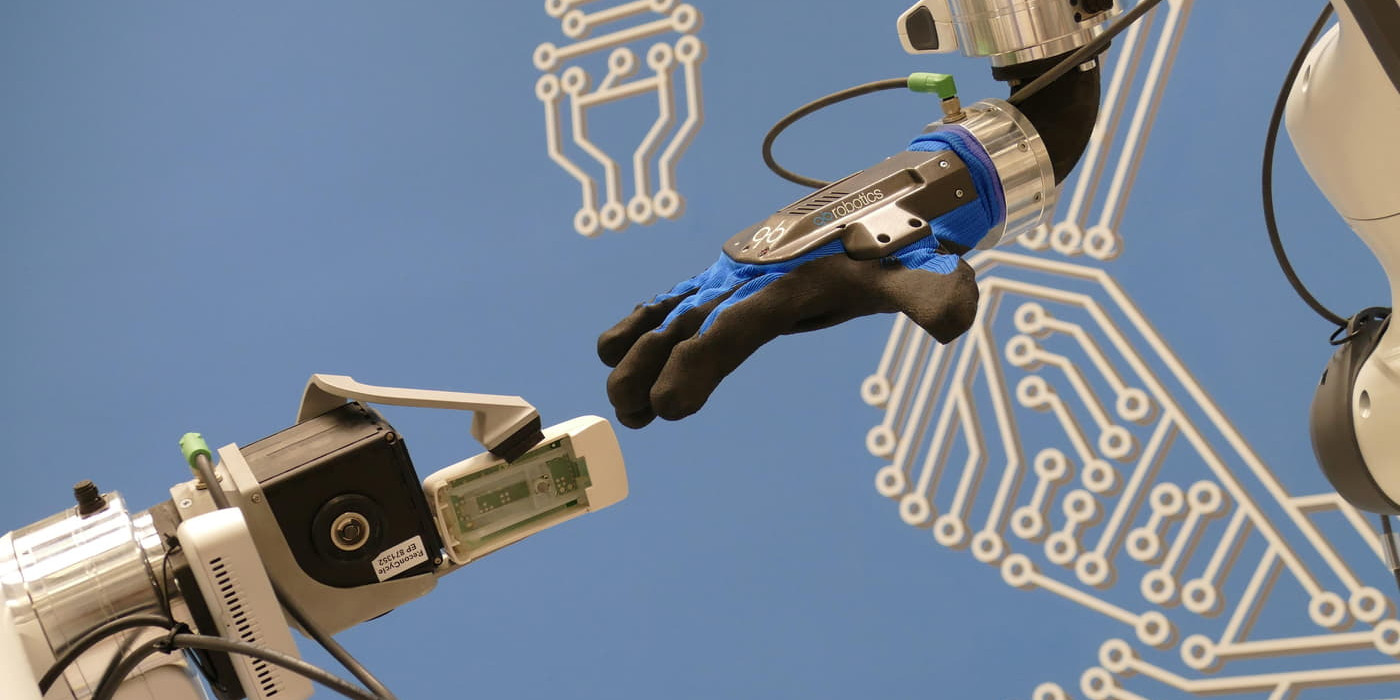

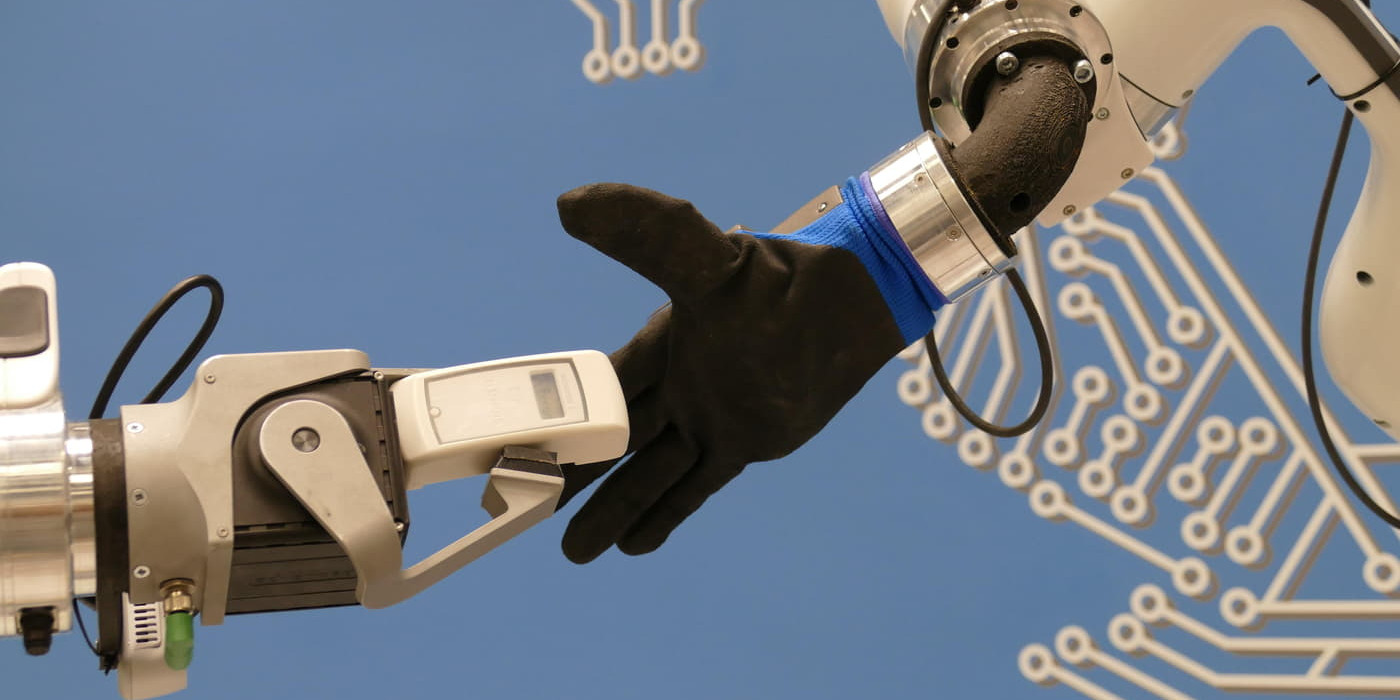

The challenge of this is to provide methodologies for re-design of the recycling cell including the location of robots and other elements in the workcell and the choice of grippers and sensing systems. On the software side, approaches for fast re-programming and adaptation of manipulation actions for soft robots and grippers suitable for recycling tasks need to be provided. Soft components make grasping and compliant control easier, but they can be problematic in assembly tasks that usually rely on high precision position control. However, high precision is less important for dis-assembly where physical constraints can guide compliant robot movements to successfully accomplish the desired task.

Industrial impact

ReconCycle aims to substantially reduce human effort and increase accuracy and efficiency of recycling. As ReconCycle uses highly compliant robots, humans will be able to operate together with the machines to complete the missing steps. This reduces automation complexity further and brings this project into a feasible regime.